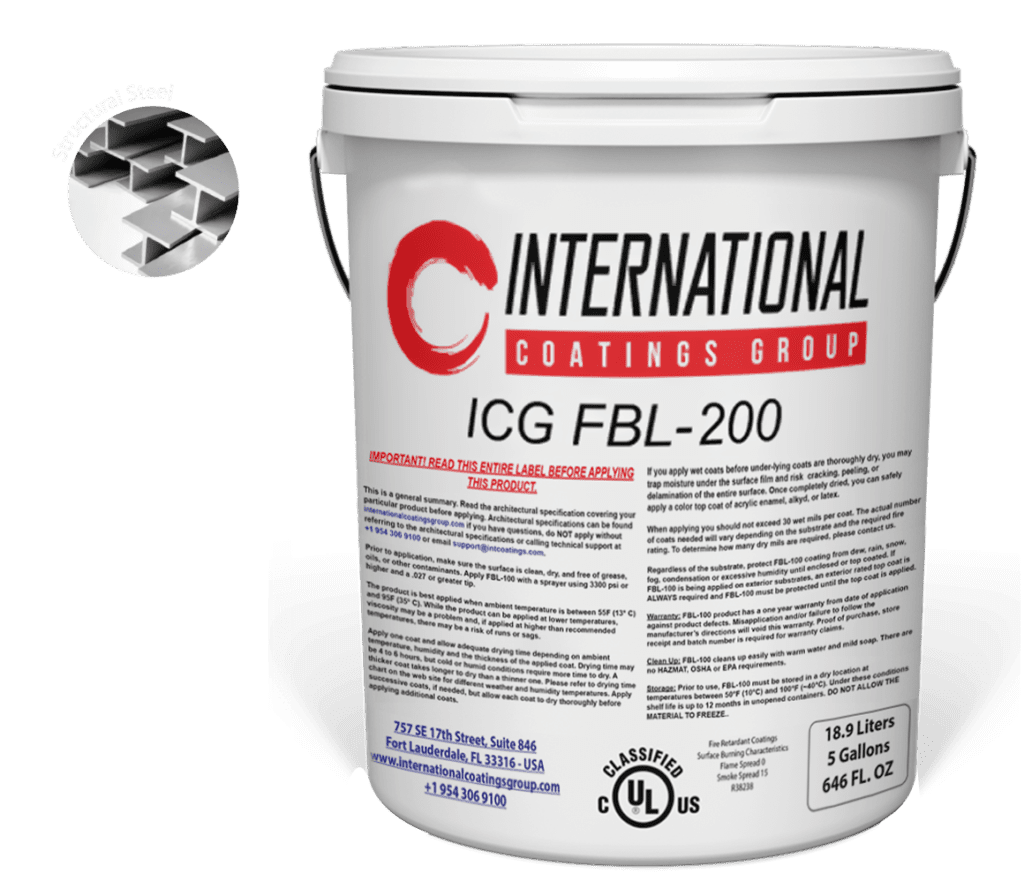

FBL-200

FBL-200 is designed specifically

for Structural Steel, with a slow

carbon char expansion – giving

up to a 2hr rating.

for Structural Steel, with a slow

carbon char expansion – giving

up to a 2hr rating.

UL AND ULC CERTIFIED

FBL-200 is a water-based intumescent thin film fireproofing material for fire protection of structural steel.

This hard, durable, abrasion resistant product has a smooth, white aesthetic finish. FBL-200 is a water-base formulation compliant with VOC limits and regulations.

APPLICATIONS

FBL-200 is specifically designed for structural steel with a slow carbon char expansion allowing for up to 2 hour ratings.

FBL-200 is UL/ULC tested and certified UL263 and CAN/ULC-S101M. UL263 and CAN/ULC-S101M are a "Standard Methods of Fire Endurance Test of Building Construction and Materials.” FBL 200 reached a 2 hour rating applicable to beams and columns.

Technical Summary

Product Category: Fire Protection Category

Product Chemistry: ACRYLIC COPOLYMER LATEX

Volume Solids: 71.44 %

Specific Gravity: 1.37

VOC: 3 g/L

Density: 1442 g/L

Average Coating Pull-Off Strength: 400 psi

D2240-05(10) Hardness test: 77

ASTM D2486 and D3450 Scrub Resistance: 172 Cycles

Percent Water Content: 28.46%

Product Chemistry: ACRYLIC COPOLYMER LATEX

Volume Solids: 71.44 %

Specific Gravity: 1.37

VOC: 3 g/L

Density: 1442 g/L

Average Coating Pull-Off Strength: 400 psi

D2240-05(10) Hardness test: 77

ASTM D2486 and D3450 Scrub Resistance: 172 Cycles

Percent Water Content: 28.46%

General SubStRateS:

FBL-100

UL / ULC certified fire retardants protection against flame and smoke spread to general substrates, such as Wood or Foam

(UL1715 / ULC-S102).

(UL1715 / ULC-S102).

QUICK LINKS

- Architects & Specifiers

- Products

- How we Compare

- Testimonials